Laying Pavers on a Curved Walkway: Perfect 2025

Why Curved Walkways Transform Your Outdoor Space

Laying pavers on a curved walkway does more than just create a path from point A to B; it creates an experience. A gentle, sweeping curve draws the eye forward, inviting exploration and making a garden feel like a journey. Unlike a rigid, straight path, a curved walkway introduces a sense of mystery and grace, encouraging a slower pace and a deeper appreciation of the surrounding landscape. While it undoubtedly requires more planning and cutting than a standard path, the stunning, organic result is well worth the extra effort.

Quick Overview: Key Steps for Installing a Curved Paver Walkway

- Plan and Mark: Use a flexible garden hose to visualize the flow of your path. Adjust it until the curve feels natural and complements your landscape.

- Excavate: Dig a trench 7-9 inches deep, ensuring the width is consistent and allows for edge restraints.

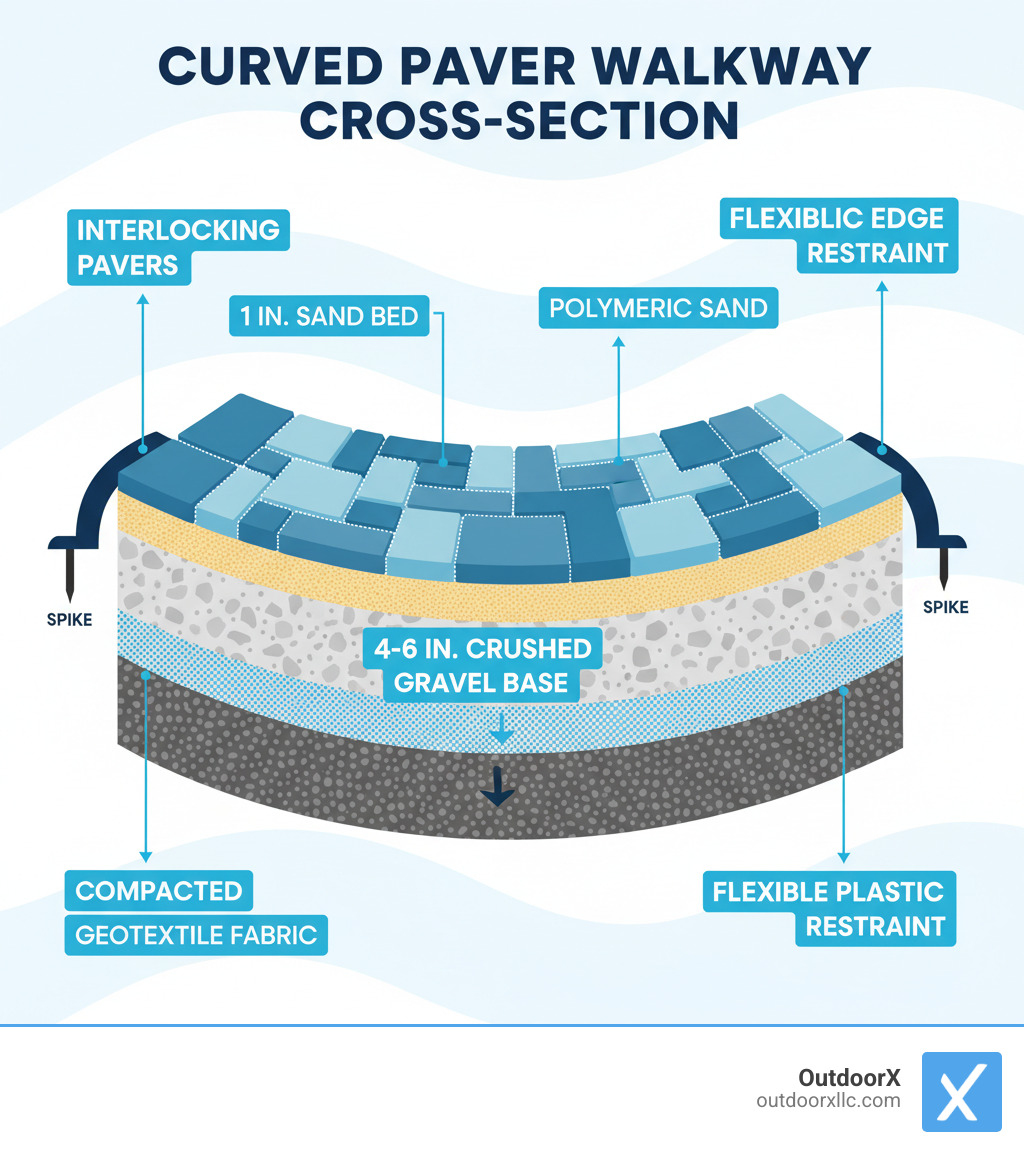

- Build a Solid Base: This is the most critical step for longevity. Add and compact 4-6 inches of gravel for a frost-proof foundation, followed by a 1-inch layer of sand to create a perfectly level setting bed.

- Lay Pavers: Start from a straight, fixed edge (like a driveway or patio) and work outward, placing pavers snugly together.

- Mark and Cut: This is where the artistry comes in. Lay pavers over your marked curve, trace the line, and use a wet saw to make precise cuts for a perfect fit.

- Install Edge Restraint: Use flexible plastic or metal edging, secured with long spikes, to lock the pavers in place and prevent them from shifting over time.

- Fill Joints: Sweep polymeric sand into the joints, compact the pavers, and lightly mist with water to activate the sand, which hardens to lock everything together and prevent weeds.

The true beauty of a curved paver walkway lies in its natural flow. It can make a compact yard feel more spacious and dynamic, creating visual interest that straight paths simply can’t replicate. But let’s be realistic: curves mean cutting pavers. A lot of cutting.

According to professional installers, a relatively simple 100-foot curved walkway can easily require 5-8 hours of dedicated cutting time. For more complex designs with tight, winding turns, that number can skyrocket to over 30 hours. This isn’t just unskilled labor; it’s time spent carefully marking, handling a powerful wet saw, and fitting each piece perfectly. That’s the trade-off for achieving that seamless, neat look.

This comprehensive guide will walk you through every stage—from planning your curve and choosing the right pavers to the precise cutting techniques that separate a professional finish from a frustrating mess. You’ll learn how to minimize cutting, work with the natural slope of your yard, and install edge restraints that actually stay put for years to come.

Whether you’re replacing an old, cracked concrete path or creating a brand-new garden walkway from scratch, the techniques detailed here will empower you to bend those pavers like a pro.

For more detailed information, you can read our guides on creating a solid base for a paver walkway, the general process of laying a paver path, and our complete overview of paver walkway installation.

Planning and Designing Your Curved Walkway

Before you pick up a shovel, let’s talk planning. The difference between a stunning, durable curved walkway and a lumpy, shifting path is almost always determined in the design phase. Thoughtful decisions here will save you headaches, wasted materials, and hours of cutting down the road.

Laying pavers on a curved walkway requires more upfront thinking than a straight path, but that’s where the magic happens. We’re talking about choosing the right materials, understanding how different patterns work with curves, and knowing exactly what tools you’ll need before you start. Proper planning is your best tool for a professional-grade result.

If the design process feels overwhelming, there’s no shame in getting expert eyes on your project. Professional hardscape design companies can help you avoid costly mistakes and create something truly special that maximizes your property’s potential.

Essential Tools and Materials

Let’s get your toolkit sorted. Having everything ready before you start makes the difference between a smooth project and constant, frustrating trips to the hardware store.

For excavation and base work, you’ll need a sturdy shovel, wheelbarrow, tape measure, and a 4-foot level. A hand tamper might suffice for a tiny landing, but for any walkway, renting a plate compactor is non-negotiable. It provides the deep, uniform compaction your gravel base needs to prevent sinking and heaving, ensuring your walkway lasts for decades.

The real star of a curved walkway project is the paver saw—specifically a wet saw with a diamond blade. The continuous stream of water cools the blade, dramatically extends its life, and, most importantly, suppresses the hazardous silica dust created from cutting concrete or stone. For intricate cuts or adjustments, an angle grinder with a diamond blade offers excellent control.

Safety gear isn’t optional: When cutting pavers, you are creating fine silica dust, which can cause serious lung disease. Always wear goggles (not just safety glasses), heavy-duty gloves, a NIOSH-approved respirator or dust mask (N95 or better), and hearing protection.

For layout and finishing, grab stakes, string line, a garden hose or flexible PVC pipe (perfect for visualizing curves), marking chalk or a paver crayon, a screed board (a straight 2×4), 1-inch square metal tubing or PVC pipes for screeding, a trowel, a rubber mallet, and snap edge cutters if you’re using plastic edge restraint.

Materials you’ll need include your chosen pavers, flexible plastic edge restraint with 10-inch spikes (shorter spikes will pull out), ¾-inch crushed stone base (also called dense grade aggregate or road base), coarse concrete sand (do not use play sand), polymeric sand for the joints, and geotextile fabric to separate your base from the soil, preventing contamination and adding stability.

Key Design Considerations for a Graceful Curve

This is where your walkway goes from “just a path” to “wow, did you hire a professional?”

Start with a garden hose or rope to outline your path. Lay it out on the ground and live with it for a day or two. Walk it. Look at it from your windows and other key vantage points. Adjust it until the flow feels natural and integrated with your landscape. Once you’re happy, mark the final path with landscape spray paint. And please, before you dig, protect yourself and your property by contacting your local utility locating service. You can learn more at the official Call 811 website. Hitting a buried utility line is dangerous and costly.

Width matters more than you think. A comfortable walkway for two people to walk side-by-side needs to be 48 inches wide. A standard single-person path is functional at 36 inches, which also allows for easy passage with a wheelbarrow or lawnmower. For wheelchair accessibility, the Americans with Disabilities Act (ADA) recommends a minimum width of 36 inches and a 60-inch by 60-inch passing or turnaround area at reasonable intervals.

Let’s talk about curve radius—how tight your curves are. Gentle, sweeping curves are neat, easier to lay, and require far less cutting. Tight, dramatic curves can be a stunning focal point but demand meticulous, time-consuming cuts and generate more wasted material. Remember the professional who spent 30-35 hours just cutting pavers for a 328-square-foot project? That was due to tight, complex curves. Be realistic about your skill, patience, and time commitment.

Drainage isn’t glamorous, but it’s crucial. Your walkway must slope to shed water. A slope of ¼-inch drop per foot away from your house or other structures is the industry standard. This prevents water from pooling, which can create hazardous ice patches in winter and erode the base material over time, leading to failure. In a climate like we have in Essex County, MA, proper drainage is essential to combat the effects of freeze-thaw cycles. If your yard already has a natural slope, use it to your advantage—fighting gravity is a losing battle.

Choosing the Right Pavers and Patterns

Paver selection can make or break your curved walkway project—both aesthetically and practically.

Modular pavers are your best friend for curves. Their smaller, uniform size and interlocking shapes are easier to handle and adapt to curved layouts. As a rule of thumb, smaller pavers accommodate tighter curves with fewer cuts and less noticeable gaps. It’s simple geometry: the smaller the unit, the more subtly it can adjust to a changing line.

Material choices each bring a unique character. Concrete pavers are the workhorse of the industry, offering best durability, consistency, and a vast array of shapes, sizes, and colors. They are typically the most budget-friendly option. Brick pavers provide a classic, traditional aesthetic that exudes warmth and timelessness. Natural stone pavers (like bluestone or granite) offer unparalleled organic beauty, with each piece being unique. However, they are more expensive and their irregular shapes and thicknesses can make them more challenging to lay and cut.

Here’s a pro tip about color: To avoid “color blocking” or patchiness, especially with variegated concrete pavers or natural stone, you must mix pavers from at least three different pallets as you work. This practice blends the natural color variations that occur during manufacturing, resulting in a cohesive, professionally blended look across the entire walkway.

Now, pattern choices for your curved paver walkway offer different levels of complexity and visual appeal.

- Running Bond: This is the simplest and most flexible pattern. Pavers are laid in rows, with the joints of each row offset from the one below, like a brick wall. It adapts well to gentle curves, minimizes the number of cuts needed, and is very forgiving for DIYers while still looking clean and professional.

- Herringbone: This pattern, with pavers set at 45 or 90-degree angles, creates a visually dynamic, interlocking surface with superior strength. It’s an excellent choice for driveways or high-traffic areas. The trade-off is its complexity; maintaining the pattern around a curve requires a significant number of angled cuts, making it a time-intensive choice best suited for experienced installers.

The pattern you choose should depend on your skill level, patience, and the tightness of your curves. For most DIY curved walkways, a running bond strikes the perfect balance between a beautiful appearance and a manageable amount of cutting.