Building a Crushed Stone Patio: Easy Master Plan 2025

Why Choose a Crushed Stone Patio?

Building a crushed stone patio is a cost-effective, DIY-friendly way to create a beautiful outdoor living space. Unlike pavers or concrete, crushed stone offers excellent drainage, natural beauty, and can be installed without professional help.

Quick Overview: Building a Crushed Stone Patio

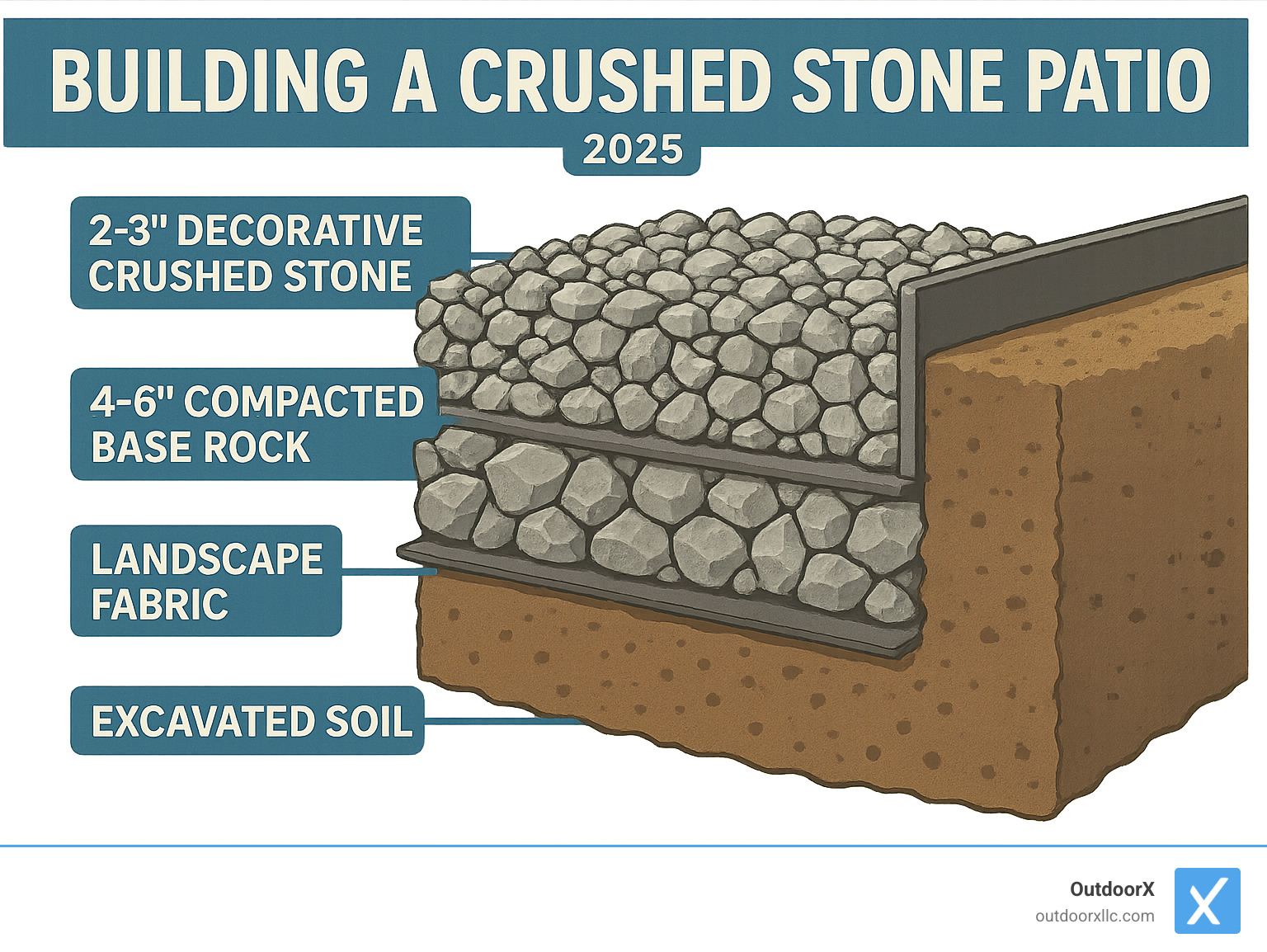

- Excavate 6-8 inches deep (up to 12 inches in cold climates)

- Install landscape fabric to prevent weeds

- Add 4-6 inches of compacted base rock

- Top with 2-3 inches of decorative crushed stone

- Edge with metal, stone, or wood borders

- Compact each layer thoroughly for stability

Here’s why crushed stone beats other patio materials:

Cost-Effective: Materials for a 100 square foot patio can be significantly cheaper than pavers or concrete. A gravel path costs about $100 per 10 feet compared to thousands for other materials.

Excellent Drainage: Its porous nature prevents puddles and reduces frost heave, making it perfect for areas with heavy rainfall.

DIY-Friendly: Unlike concrete, it requires only basic tools and can be a weekend project, with a difficulty rating of just 1 out of 5.

Natural Beauty: Crushed stone complements any landscape style and comes in various colors from warm Cotswold Buff to neat Polar White Marble.

Low Maintenance: Maintenance is simple: just occasional raking and topping up, with no sealing or crack repairs needed.

Building a crushed stone patio word list:

Planning Your Perfect Patio: Materials, Tools, and Costs

Success in building a crushed stone patio starts with smart planning. It saves time, money, and frustration. Let’s cover materials, tools, and costs.

First, consider patio design and site selection. Where will the patio get the most use? How much space do you need? A good rule is to add at least 3 feet around your outdoor furniture for walking space.

Next is budgeting. While crushed stone is budget-friendly, costs for tool rental, edging, and delivery add up. The good news is that most tools can be rented.

For material calculation, always order 10-15% extra stone to account for compaction and avoid extra trips to the supplier. Rent tools like plate compactors only for the days you need them to save money. Speaking of excavation, this is where our hardscaping knowledge really pays off.

Choosing the Right Crushed Stone

This choice affects not just aesthetics but also the patio’s stability and longevity.

The key decision is angular versus rounded stone. Angular stone interlocks when compacted, creating a stable base. Rounded stone, like pea gravel, is less stable and better for decorative top layers.

Stone size also matters. Larger stones (3/4 inch to 1 inch) are great for base layers, while smaller stones (1/4 inch to 1/2 inch) create smoother top surfaces.

Color options can transform your patio. Choose colors that complement your home. Local availability often determines the best choices and keeps costs down.

| Crushed Stone Type | Pros | Cons | Best Use | Average Cost (per ton)* |

|---|---|---|---|---|

| Crushed Limestone | Excellent compaction, forms firm base, permeable | Can be dusty, may contain fines | Base layer, sub-base for flagstone | $30 – $95 |

| Pea Gravel | Smooth underfoot, aesthetically pleasing, good drainage | Doesn’t compact well, can shift | Top decorative layer, pathways | $30 – $95 |

| Decomposed Granite (DG) | Compacts very well, natural look, permeable | Can track indoors, may require stabilizer | Walkways, patios, garden paths | $40 – $125 |

| Crushed Granite | Very durable, stable, sharp edges for interlocking | Can be sharp on bare feet, expensive | Base layer, high-stability areas | $40 – $130 |

Note: These are average costs based on internet data and not actual costs for OutdoorX LLC. Prices vary significantly by location and supplier.

Essential Tools and Materials

The right tools make building a crushed stone patio a manageable project. Some you may own, while others can be rented or bought.

For digging and moving, you’ll need a square-edged spade, a round-point shovel, and a wheelbarrow. A metal rake is best for spreading and leveling stone.

A plate compactor is essential for a stable base and can be rented for about $65 per day. For larger patios, a walk-behind Bobcat or mini track loader (around $140 per day) speeds up excavation.

For layout, you’ll need stakes and string, a line level or builder’s level, a tape measure, and a utility knife.

Don’t forget a hammer and wood block for edging, a tarp for soil, and safety gear (gloves, glasses, mask, boots). Materials include landscape fabric, edging material, your chosen crushed stone, and a garden hose.

Estimating Costs and Materials

Correct calculations prevent extra supply runs. To calculate cubic yards, multiply length × width × depth (all in feet), then divide by 27.

For a 10-foot by 10-foot patio needing a 6-inch base layer: 10 × 10 × 0.5 = 50 cubic feet. Divided by 27 = 1.85 cubic yards of base stone.

Material delivery (often $50-$100) saves time and is more economical for larger projects than buying bags. Budget about $200-300 for a weekend of specialized tool rentals.

For a 100 sq. ft. patio, base materials can cost $400-$1300+. Adding the top layer, edging, fabric, and rentals brings total project costs to a price range of $400-2500+. The wide range reflects choices in stone, site conditions, and DIY vs. hired help.

These are average costs based on internet data and not actual costs for OutdoorX LLC. Actual prices vary significantly based on location, supplier, materials chosen, and project complexity.

The investment pays off, as professional installation can cost $3,000-8,000+, and there’s great satisfaction in DIY.

The Step-by-Step Guide to Building a Crushed Stone Patio

Now for the fun part. Building a crushed stone patio is about creating supportive layers. The secret to a long-lasting patio is taking your time with the foundation. A solid base prevents a wobbly, uneven surface later on.

Step 1: Excavation and Site Prep

Good site prep is the key to a lasting patio.

First, mark the perimeter with stakes and string, a hose, or marking paint. This is your last chance to easily adjust the patio’s footprint.

Before digging, call 8-1-1 to have underground utilities marked. Hitting a utility line is dangerous and costly. This service is free, required by law, and essential for safety.

For digging, remove the sod first. Excavate 6-8 inches deep in most climates. In cold regions, dig up to 12 inches to prevent frost heave, which can create a bumpy surface.

The most critical part is creating a slope for drainage away from your house. Aim for a 1/8 to 1/4 inch drop per foot to prevent pooling water and potential damage. Use a line level to get this right. For more complex drainage situations, Hardscape Drainage Solutions can provide additional guidance.

Once dug, rake the area smooth and compact the subsoil with a hand tamper for a firm, even surface.

Step 2: Laying the Foundation

A solid foundation ensures stability and drainage for years. Don’t cut corners here.

First, compact the subsoil. Thoroughly compact the exposed earth with a plate compactor or hand tamper to create a stable platform that prevents settling.

Next, install the landscape fabric. This fabric is crucial. Roll it out over the excavated area, overlapping strips by at least 4 inches. It prevents weeds and stops stone from mixing with the soil. Secure it with landscape pins. The experts at Fine Homebuilding have great insights on this crucial step in Getting Patio Bases Right – Fine Homebuilding.

Now for the base rock layer. Add a 4-6 inch layer of angular crushed stone (like 3/4-inch crushed rock). The angular edges interlock when compacted, creating a solid, non-shifting foundation.

The most important part is compacting in lifts. Spread the stone in 2-3 inch layers, lightly dampen each one, and compact it thoroughly with a plate compactor. This removes air pockets and creates a rock-solid base.

Step 3: Adding the Top Layer of Crushed Stone

This is the finishing step, where the patio takes its final form.

Spreading the decorative stone is next. Pour your chosen decorative stone onto the compacted base and spread it evenly with a rake for a smooth, professional look.

Achieving the final depth is crucial. Aim for a 2-3 inch depth. Less can expose the base; more makes walking difficult and furniture unstable.

Leveling with a rake gives a smooth finish. Work across the patio, checking for high and low spots. Finally, mist the surface with water to settle dust and help the stones lock into place.

Step back and admire your work – you’ve just built a beautiful, functional patio that should serve you well for many years to come!

Finishing Touches and Long-Term Maintenance

These final steps ensure your patio looks great and lasts for years.

Best Practices for Edging and Containment

Edging is the frame for your patio. Without it, stones will spread into the surrounding landscape. It keeps stones contained and provides a clean, polished border.

Metal edging offers a sleek, durable, and modern look. Stone or brick borders provide a timeless, substantial feel. Plastic edging is a budget-friendly, flexible option. Wood timbers offer a rustic look; use pressure-treated or rot-resistant wood like cedar.

Install edging in a shallow trench so it sits about half an inch above the final stone surface. This lip prevents stone migration. Secure metal and plastic edging with the included spikes. For stone and timber, backfill with soil packed firmly against the outside edge for support.

Maintaining Your Crushed Stone Patio

The best news? Maintaining a crushed stone patio is simple. No sealing, pressure washing, or crack repairs are needed.

Raking and smoothing every few months redistributes stones shifted by foot traffic.

Topping up with a thin layer of fresh stone replaces any material that has been displaced or compacted over time.

Weed control is minimal thanks to the landscape fabric. Pull any stray weeds by hand or use a natural weed killer like vinegar.

Cleaning is easy. Sweep away debris, rinse spills with a hose, and use mild soap for tougher stains. Avoid aggressive pressure washing.

Seasonal care involves clearing fallen leaves to prevent them from decomposing and creating soil for weeds.

Common Mistakes When Building a Crushed Stone Patio

Learning from common mistakes saves time, money, and frustration. Avoid these errors:

Skimping on excavation depth: Shallow bases lead to wobbly, settling patios. Dig 6-8 inches deep, or up to 12 inches in cold climates.

Rushing the compaction process: Hand tamping isn’t enough for a patio; a plate compactor is essential for professional results.

Forgetting landscape fabric: This barrier is well worth the time and cost to prevent weeds.

Ignoring proper drainage slope: An improper slope creates puddles. Ensure a gentle slope away from your house.

Skipping the edging: Without containment, you’ll be constantly raking stones back into place.

Frequently Asked Questions about Building a Crushed Stone Patio

Here are answers to common questions about building a crushed stone patio.

How deep should a crushed stone patio be?

The correct depth is crucial for a long-lasting patio and depends on your climate.

For excavation depth, dig down 6-8 inches in most climates. In cold climates with freeze-thaw cycles, go deeper—up to 12 inches—to prevent frost heave.

Your base layer of compacted crushed stone should be 4-6 inches thick. This is the patio’s foundation. On top, your decorative top layer needs to be 2-3 inches deep. Less can expose the base fabric, while more makes walking difficult.

How do you keep crushed stone from moving?

To keep stone from moving, make smart material and installation choices.

Choose angular stone over rounded stone for your base. The sharp edges lock together when compacted. Rounded pea gravel is unstable and not ideal for a base.

Sturdy edging is your best friend. A border of metal, stone, or wood acts as a fence to contain the stone.

Proper compaction is critical. Thoroughly compacting each layer creates a dense, interlocked surface that resists movement.

Finally, stick to a 2-3 inch depth for your top layer. Deeper top layers are unstable and more likely to scatter.

Can you put furniture on a crushed stone patio?

Yes! Your crushed stone patio is perfect for outdoor furniture.

Furniture with wide feet or bases works best. It will be more stable than items with skinny legs, which can sink.

Distribute weight evenly. A clever trick is to place flagstones or concrete pavers under table legs for added stability while maintaining the patio’s look.

The result is a stunning, permeable patio with perfectly stable spots for your furniture.

Ready to Create Your Dream Outdoor Space?

Building a crushed stone patio is a satisfying DIY project that transforms a yard into a beautiful, long-lasting outdoor living space. A well-built crushed stone patio is durable, low-maintenance, and ages gracefully. The money you save on this DIY project can be used for new outdoor furniture or a fire pit.

Of course, not everyone has the time or tools for a major project. For challenging terrain or complex designs, the smartest decision is often to call in the experts.

That’s where professional help is invaluable. Experts can handle complex designs, drainage issues, and deliver a picture-perfect result.

At OutdoorX, we transform outdoor spaces throughout Essex County, MA. From South Hamilton to Ipswich and Manchester-by-the-Sea, we bring quality craftsmanship to every project, creating beautiful, functional outdoor areas customized to your lifestyle.

If you’re dreaming of a stunning patio but prefer to leave the heavy lifting to the pros, we’d love to help bring your vision to life. Check out our Patio Design & Installation services to see how we can help you create the outdoor oasis you’ve always wanted – without the sore back!